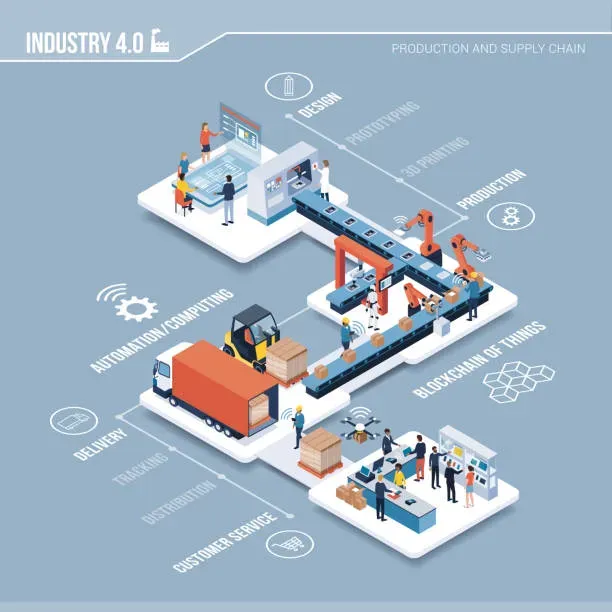

Industry 4.0 in manufacturing is redefining how products are designed, produced, and delivered, signaling a shift toward smarter, more responsive, and data-driven operations that scale with demand, minimize friction, and elevate customer value across value chains. The move toward smart factories on the shop floor creates a tightly coordinated network of machines, sensors, and software that delivers real-time visibility, supports proactive scheduling, rapid deviation detection, and continuous optimization of throughput. Digital twins enable teams to model assets and processes virtually, test changes safely, validate performance against live baselines, and simulate end-to-end scenarios, reducing risk and accelerating time-to-market for new products. As data flows across integrated platforms, data analytics informs decisions that improve quality, minimize waste, optimize energy consumption, and enhance OEE, turning operational data into actionable insights that drive sustained competitive advantage. Together, these capabilities foster a resilient, adaptable manufacturing ecosystem that accommodates customization, shortens product cycles, and strengthens supply chains, while enabling a culture of continuous improvement grounded in measurable outcomes.

Also referred to as smart manufacturing and the digital transformation of production, this shift blends cyber-physical systems, connected devices, and cloud analytics to create networks where information guides every step of the value chain. By leveraging IIoT networks, edge intelligence, and digital twin-driven simulations, plants become more adaptive, turning data into real-time guidance for maintenance, scheduling, quality control, and supplier collaboration. The focus expands beyond automation to a holistic approach that aligns people, processes, and technology, enabling agile decision making, resilient supply chains, and sustainable operations across product lifecycles.

Industry 4.0 in manufacturing: Transforming the Way Products Are Designed and Produced

Industry 4.0 in manufacturing is reshaping how products are designed, produced, and delivered. It blends digital technologies with physical operations to create smarter, more agile factories that can quickly adapt to customization, shorter product lifecycles, and intense global competition.

By weaving together sensors, connected devices, and advanced analytics, modern plants gain end-to-end visibility across the value chain and can anticipate disruptions before they impact output.

Smart Factories and the Real-Time Control Loop

In a smart factory, machines, sensors, and controllers share data in real time to balance production, quality, and throughput, enabling dynamic scheduling and autonomous quality control.

This real-time control loop reduces variability, enables rapid response to deviations, and frees human workers to focus on higher-value tasks while maintaining rigorous process discipline.

Industrial IoT as the Data Backbone of Modern Manufacturing

industrial IoT (IIoT) connects sensors and devices across the shop floor, delivering continuous data streams that illuminate OEE, energy use, and throughput at granular levels.

With strong data governance and interoperable interfaces, managers can break data silos, unify reporting, and enable scalable analytics across multiple plants and lines.

Digital Twins and Predictive Maintenance for Higher Uptime

Digital twins mirror a physical asset or process, allowing engineers to run simulations, test scenarios, and optimize performance virtually before implementing changes on the shop floor.

Applied to maintenance planning, digital twins fuel predictive maintenance, extending asset life, reducing unplanned downtime, and improving overall equipment effectiveness (OEE).

Data Analytics in Manufacturing: Turning Data into Action

Data analytics in manufacturing turns vast sensor and process data into actionable insights that guide decisions in procurement, production, and logistics.

AI and machine learning detect patterns, enable anomaly detection, optimize schedules, and support smarter decision-making—driving lean operations and faster ROI.

Security, Governance, and Interoperability in Industry 4.0 Environments

As connectivity expands, robust cybersecurity, data governance, and privacy protections become foundational to safe and reliable manufacturing ecosystems.

Emphasize interoperability through open standards and compatible interfaces—such as OPC UA or MTConnect—and implement continuous monitoring, access controls, and risk management to protect operations.

Frequently Asked Questions

What is Industry 4.0 in manufacturing and how do smart factories enable real-time operations?

Industry 4.0 in manufacturing is the integration of digital technologies with physical operations to create smarter, more agile factories. Smart factories leverage connected devices, sensors, and cyber-physical systems to monitor production in real time, enable autonomous responses to deviations, and improve OEE, quality, and flexibility.

How does Industrial IoT (IIoT) empower Industry 4.0 in manufacturing for asset health and OEE?

IIoT connects sensors and equipment across the shop floor, delivering continuous data on asset health, performance, energy use, and throughput—critical in Industry 4.0 in manufacturing. This visibility enables proactive maintenance, tighter process control, and measurement of OEE, supporting the goals of Industry 4.0.

What role do digital twins play in Industry 4.0 in manufacturing for virtual testing and optimization?

A digital twin creates a living model of a physical asset or process, allowing engineers to simulate changes, test scenarios, and optimize performance without risking production in Industry 4.0. Digital twins accelerate design decisions and reduce downtime through safer, faster experimentation.

How can data analytics in manufacturing drive predictive maintenance within Industry 4.0?

Data analytics in manufacturing processes large data streams from sensors to detect patterns and anomalies, enabling predictive maintenance that schedules service before failures occur in Industry 4.0. This reduces unplanned downtime, extends asset life, and supports smarter decision-making across the production value chain.

What are the key cybersecurity and data governance considerations when scaling smart factories under Industry 4.0 in manufacturing?

As connectivity expands, robust cybersecurity, role-based access, and data governance become critical when scaling smart factories under Industry 4.0 in manufacturing. Implement layered security, regular risk assessments, and clear data ownership to maintain trust and compliance while scaling.

What is a practical roadmap to implement Industry 4.0 in manufacturing, including pilots for IIoT, digital twins, and analytics?

Begin with a focused pilot on a single line to validate IIoT sensing, digital twins, and data analytics in manufacturing, then scale to broader operations. Build a data strategy, establish governance, and pursue interoperable platforms to realize measurable gains in uptime, quality, and efficiency.

| Aspect | Key Points |

|---|---|

| Definition | Convergence of the physical and digital worlds; cyber-physical systems, Industrial IoT, and cloud-based analytics enable data-driven decisions, transparency, and agile operations. |

| Core Technologies | IoT/IIoT, Digital Twins, AI/ML, Edge Computing, Robotics & Automation, Cybersecurity & Data Governance. |

| Benefits |

|

| Practical Roadmap |

|

| Challenges & Considerations |

|

| Real-World Examples | Automotive and consumer electronics use IIoT sensors for real-time condition monitoring and automated quality checks; digital twins of packaging lines help simulate product introductions and optimize throughput; these prove that data-driven insights drive concrete improvements in OEE, throughput, and energy efficiency. |

| Future Outlook | AI models become more capable, edge devices proliferate, and automation adapts to dynamic networks and changing demand; partnerships across the value chain grow, sustainability goals align with digital transformation, and digital threads connect design, production, and service for new business models. |

Summary

Key points table generated to summarize the base content on Industry 4.0 in manufacturing.